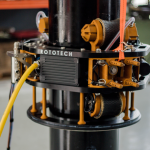

Rototech is focused on the sustainability of tomorrow’s world. At the core of our industry, fossil fuels remain as prevalent as ever, that’s why we’ve developed technologies designed specifically at maintaining offshore assets to ensure the highest standards of safety are maintained, reducing the risk of oil spills and other ecological disasters as well as reducing the carbon footprint whilst performing the task.

Our technology also extends into the renewable energy industry, namely offshore wind turbines. In the harsh conditions at sea, it’s crucial that all assets, whether fossil fuel or renewable, are maintained at a low-cost and with as little environmental impact as possible.